ABOUT

- Technology

- About

With many years of skilled engineering experience over the competition, B&I Dash Kits are well established as the best fitting in the industry. Unfortunately for consumers, how well a kit fits cannot be gauged by looking at a photo or schematic, which is why poor fitting kits are common place in this industry. A poor fitting kit can include pieces with oversized hole cutouts, uneven edges and pieces that look good installed, but, peel off in time because they are engineered to fit over extreme curves that exceed bond capabilities.

Before engineering work is authorized, B&I's experienced Design Team carefully studies each interior to insure only pieces that add value and style are selected to be engineered. The competition, on the other hand, generally rely on one inexperienced person who both configures and engineers their kits. The result is often an excessive number of poor fitting pieces that clutter and destroy the interiors factory look.

Using revolutionary Factory TruMATCH Technology, B&I's experienced Color Masters produce the most accurate and consistent color and grain pattern matches in the industry. These special finishes are part of B&I popular Factory Match kits that are made to match the vehicles existing wood trim and cover obvious areas left bare and unfinished from the factory.

B&I uses premium 3M 5849 Acrylic Foam Adhesive that does not require the tedious, messy and time-consuming application of promoter during installation. The extended cure time of this premium adhesive allows you to reposition your dash parts for perfect fitting, while other adhesives bond on contact with no room for error. Also, there is no risk of accidentally damaging other factory parts with promoter contamination and there is no risk of promoter contact with those with sensitive skin.

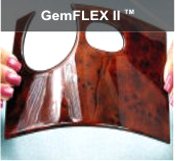

In addition to a brilliant high gloss finish, B&I's high performance polyurethane clear coat has several outstanding features, including; an ultra thin profile for a more factory-like appearance, incredible flexibility for easier installation and advanced inhibitors to prevent cracking and discoloration that can occur from prolonged exposure to extreme temperatures and harmful UV rays.

B&I invented ClearVUE Technology to create a more factory-like appearance on dash trim pieces that fit over top of illuminated symbols, such as a radio piece with a "PWR" symbol. ClearVUE creates a smooth, poured surface overtop of hole cutout made to allow the illuminated symbol to shine through, as opposed to competing products that pour around these hole cutouts creating an unnecessary cavity.

B&I, a division of TACNA International Corporation, is Head Quartered in San Diego, California and is a leading manufacturer of automotive trim products for both interior and exterior applications. Currently, B&I product offering includes 2D and 3D Dash Trim, Wood and Leather Wrapped Steering Wheels, Custom Dipping, Rocker Panels, Fender Trim and Pillar Posts.

With 20 years selling to the aftermarket worldwide, they have gained the experience and ability required to serve a diversified range of customers from OEM's to Mobile Installers. Strategic advantages include:

- Persistent focus on customer requirements

- Industries most experienced sales and support team

- Customer dedicated marketing team

- Exclusive product selling features

- 1st-to-Market product development

- Low-cost-center manufacturing

- Lean principled manufacturing

- Data driven management

- Complete 'new project' responsibilities

- In-House design and engineering

- Various equipment and technology resources

- Rapid low-cost tooling and prototyping

- Heavy focus on research and development

- Commitment to ISO/TS 16949 certification

- Continuous improvement programs

- Operational audit programs

- Process control systems

- In-house product testing