Product Line

- Rotor and Pad Kits

- Brake Pads

- Brake Rotors

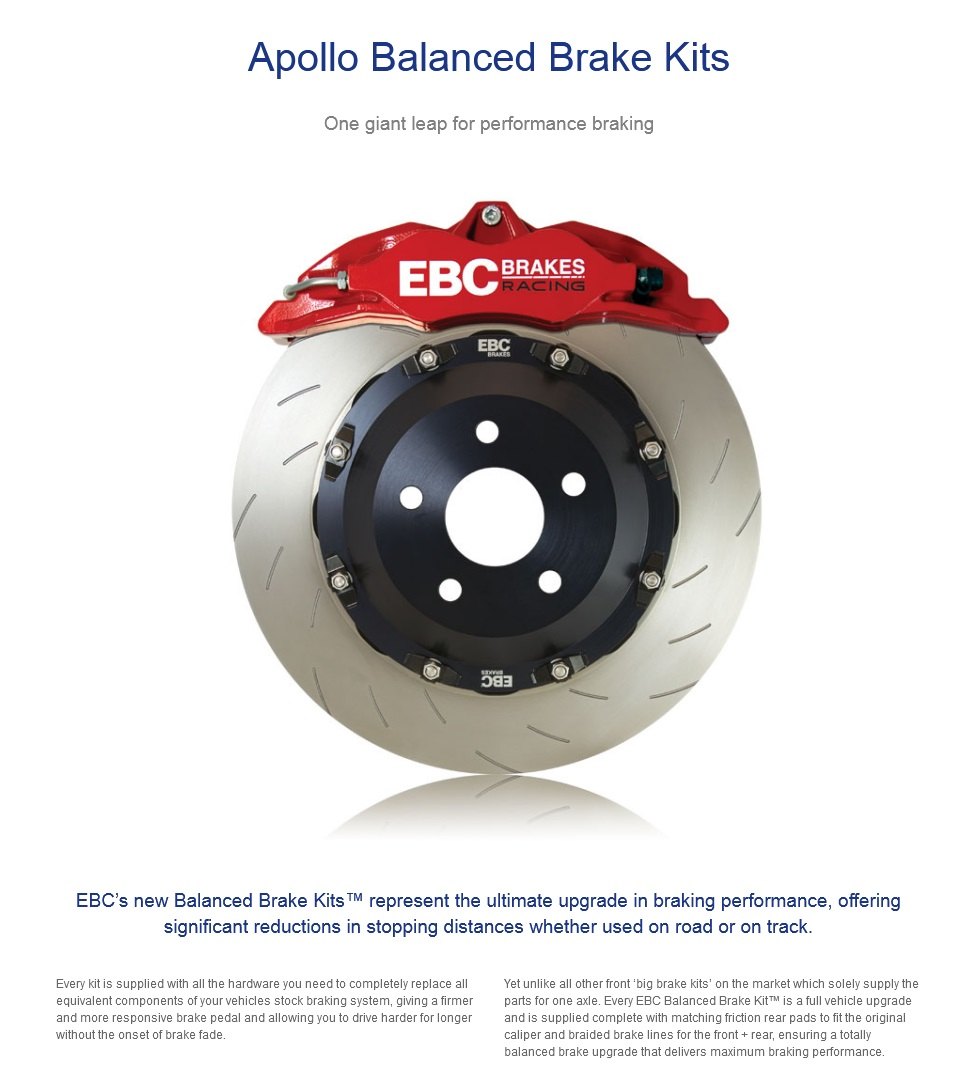

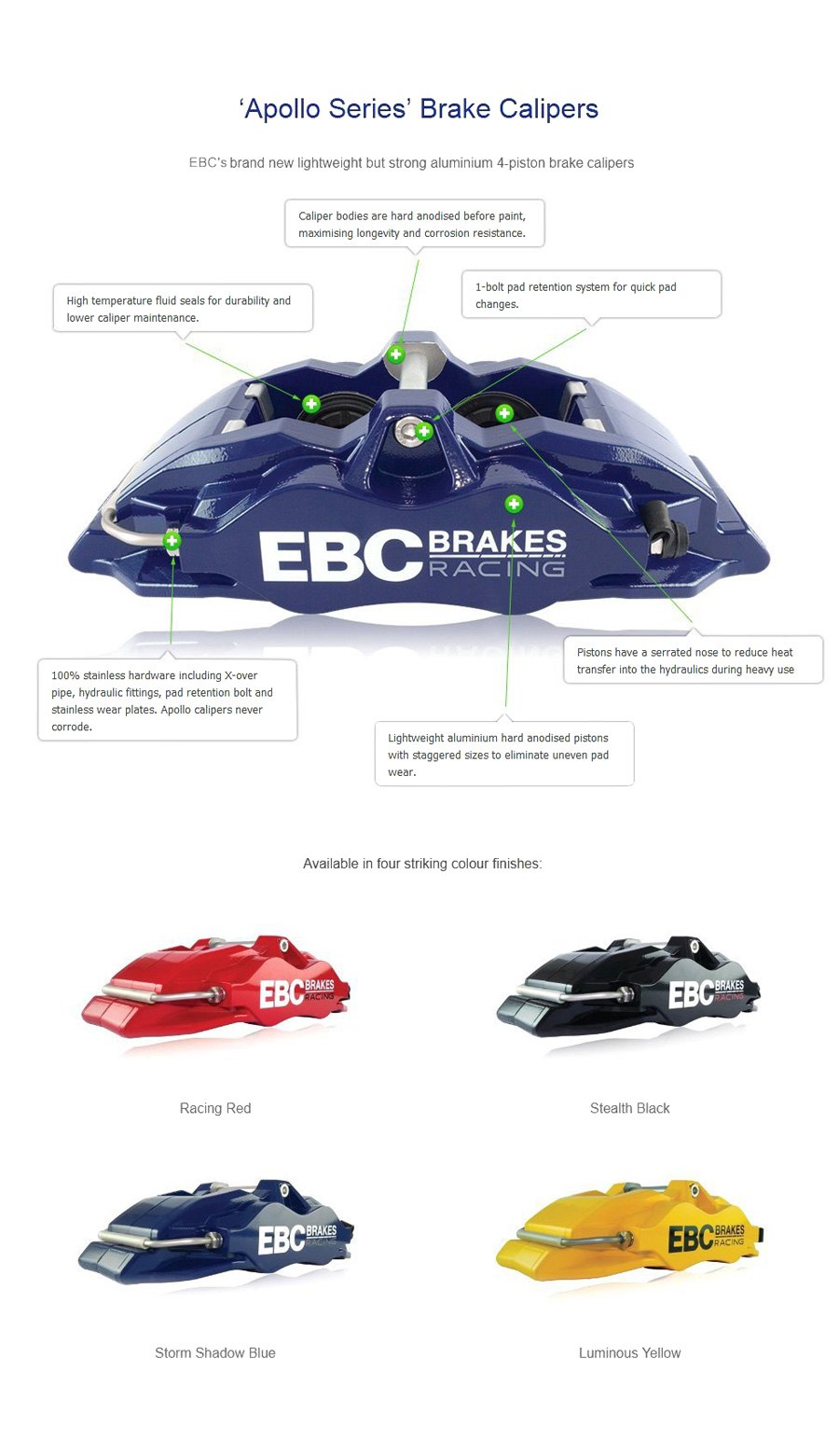

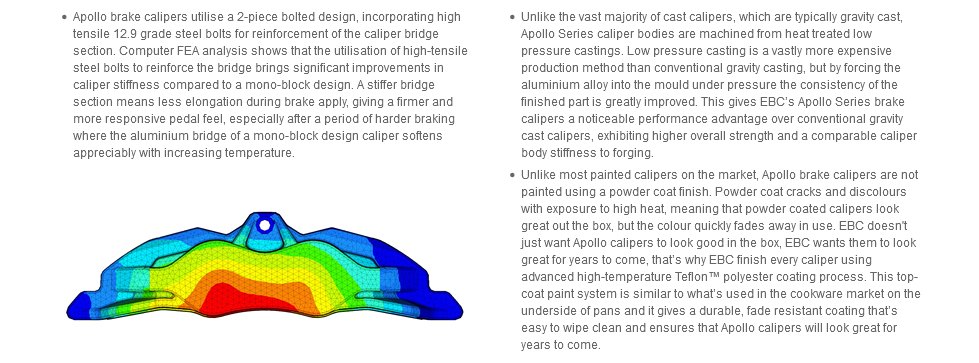

- Apollo Balanced Brake Kits

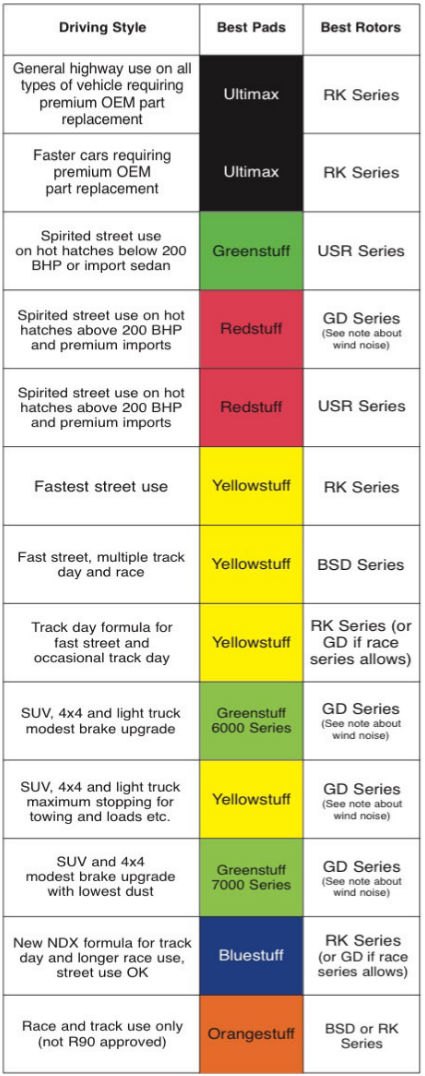

- Selector Chart

- Stage 1 Premium Street Brake Kit

-

Enhance your daily driving with confidence and peace of mind. With the EBC Stage 1 Premium Street Brake Kit, you will forget about brake shudder or embarrassing brake squeal when coming to a stop. The kit combines the Ultimax Pads and stock replacement rotors for the ultimate OEM pad and rotor combination at an affordable price.

Rotors Features:

- Sized and shaped to original equipment specifications with extremely tight tolerances

- Designed to meet or reduce factory levels of heat buildup, brake noise, vibration, and wear

- Black GEOMET and NITROTHERM™ anti-corrosive finish

- Recommended by EBC for normal street driving, high performance street driving, truck or SUV use, drifting, and short track runs

- High quality "gray" iron features a higher carbon content to reduce brake shudder, heat cracking, and high-frequency vibrations which cause squealing

- Vented center allows air to pass between both rotor sides for more effective cooling

- EBC recommends a 500 mile break in period with lighter braking application

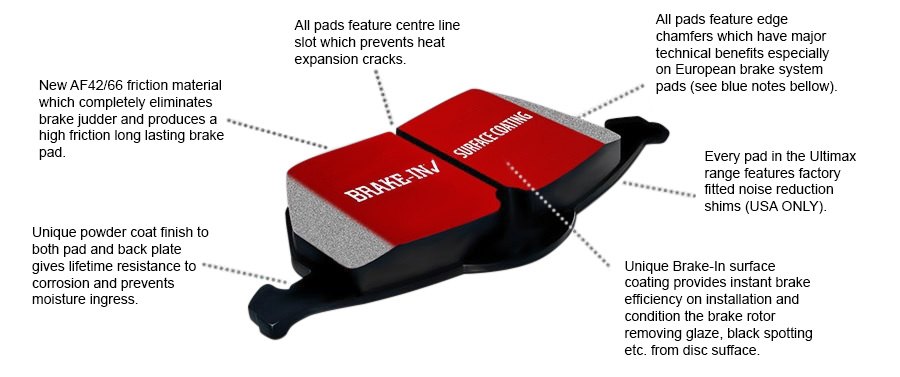

- Patented AF42/66 pad friction material features a low level of metallic compounds that reduces rotor wear by up to 50%

- Produces low amount of brake dust

- Backing plate and side edges of brake pad are black powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built-in noise-reducing shims

- Patented Brake-In™ red top coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red top coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

Brake Pads Features:

- Patented AF42/66 pad friction material features a low level of metallic compounds that reduces rotor wear by up to 50%

- Produces low amount of brake dust

- Backing plate and side edges of brake pad are black powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built in noise-reducing shims

- Patented Brake-In™ red top coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red top coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

Why pay dealership prices that are marked up 100% when you can purchase EBC high-quality RK Series Premium OE Replacement rotors for less? Unlike cheaper, inferior replacement rotors that may look identical to original equipment, EBC builds these to match original factory dimensions and machines them to extremely tight tolerances. But they did not stop there. EBC has applied their engineering expertise to create an iron compound that exceeds the quality of most original material blends, so these rotors actually improve on factory levels of heat buildup, brake noise, vibration, and wear. A higher percentage of carbon and silicone is present which leads to the formation of graphite during the curing process. When graphite is present, the rotor itself takes on qualities of a denser, softer material. Heat is more evenly dispersed to reduce warping, cracks are less likely, and vibration-related noise is greatly reduced. RK Series Premium OE Replacement Rotor Kit is anodized for corrosion resistance, and rotors should be fully ready for performance driving after a 500 mile break-in period.

EBC Ultimax OEM Replacement Brake Pads are designed to match the exact dimensions of original equipment with extremely tight tolerances to ensure proper fit, even wear, and absence of rattles and squeaks. A patented low-metallic aramid compound uses DuPont Kevlar and Twaron composites to reduce the amount of steel wool necessary, so these pads cause far less abrasive wear on rotors without compromising brake pad efficiency or longevity. In government R90 tests of replacement brake components, EBC pads have shown to deliver equivalent performance, bedding, cold temperature operation, and speed sensitivity when compared to original manufacturer parts. EBC’s aramid material also ensures the pads are soft enough to avoid brake squeal, but not so soft that pad longevity becomes compromised. On some German vehicles, you may even see longer life with EBC pads than the original factory brake pads provided.

If you’re installing Ultimax OEM Replacement Brake Pads with new brake rotors, you’ll find down the road when the time comes to replace the pads again, rotors will still be usable enough to last through another set of brake pads. And if you are installing EBC pads without replacing rotors, pre-chamfered pad edges will mate perfectly against the grooves and lips that normally form on the rotor surfaces, so the meat of the pad makes contact against the rotor center where it counts. These pads also feature a red top layer coating designed to scour glaze and hot spots off worn brake rotors during the break-in process. As it does that, the coating also serves to provide a higher level of grip to counteract low friction levels that exist before bedding is complete. Built-in shims ensure any high-frequency vibration is absorbed rather than transferred as squealing noise, even under the most extreme weather conditions. EBC backs their replacement brake pads with a 6-month or 10,000 mile warranty against premature wear under normal driving conditions.

- Stage 2 Sport Brake Kit

-

Replace your old, worn out brakes with better performing pads and rotors from EBC. The Stage 2 Sport Brake Kit is designed to increase your stopping power and produce less brake dust than your stock brakes. The 2000 Series brake pads paired with the Ultimax rotors are sure to do their job very well every time you hit the brakes.

Rotors Features:

- Created to be the lowest noise brake rotors designed for performance applications

- Angled slots on rotor surfaces allow superior expulsion of heat, water, brake dust, and friction gases

- Two sets of slots on rotor surfaces provide even pad wear which creates flat, parallel rotor wear without ridges from developing

- Rotors feature protective finish to provide corrosion protection for all non-contact areas

- Brake rotors are unidirectional to the left and right side of your vehicle to maximize effectiveness

- EBC recommends a 500 mile break in period with lighter braking application

Brake Pads Features:

- Designed to give a high level of grip upon initial brake application

- Engineered for optimum performance on lighter vehicles with horsepower ratings under 200

- Nominal friction coefficient of 0.55

- Offers superior brake performance up to temperatures of 1,100° Fahrenheit

- Patented organic AF42/66 pad friction material features a low level of metallic compounds that reduces rotor wear by up to 50%

- Produces low amount of brake dust

- Backing plate and side edges of brake pad are green powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built in noise-reducing shims

- Patented Brake-In™ red pad surface coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red pad surface coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

- 6 month/10,000 mile manufacturer warranty against premature pad wear under normal driving conditions

USR Series Sport Slotted Rotors are created for the enthusiast who wants low noise from their brakes while doing a higher level of aggressive driving or towing. Two sets of shallow slots cover all areas of the rotor surfaces so both pads and rotors wear evenly all the way across – preventing the grooves and ridges from building up that cause frictional noise. They also effectively increase the level of heat, water, brake dust, and friction gas expulsion necessary to keep rotors cool and functional during street performance driving in any weather. Additionally, USR Series Sport Slotted Rotors feature a vented center for air to pass between both rotor sides, so metal expands evenly during use and the chance of warpage is minimized. USR Series Sport Slotted Rotors are designed for use with EBC Greenstuff, Yellowstuff, and Redstuff pads. All areas of the rotors have a protective coating to prevent corrosion, and should be fully ready for use after the first 500 miles of moderate brake application.

For less powerful vehicles that don’t usually travel at triple-digit velocity, EBC Greenstuff 2000 Series Sport replacement brake pads offer better braking power at real world driving speeds and are thus formulated to provide longer pad life instead of autobahn grip. Sized and fitted to match the exact tolerances of original equipment, these pads fit properly, wear evenly, and avoid rattling or squealing. A patented metallic aramid compound uses DuPont Kevlar and Twaron composites to minimize the amount of steel wool necessary, so these pads cause far less abrasive wear on rotors without compromising brake pad efficiency or longevity. In government R90 tests of replacement brake components, EBC pads have been shown to deliver equivalent performance, bedding, cold temperature operation, and speed sensitivity versus original manufacturer parts. EBC’s patented brake pad material also ensures the pads are soft enough to avoid brake squealing but not so soft that longevity becomes compromised. On some German vehicles, you may even see longer life with EBC pads than the original factory brake pads.

If you’re installing Greenstuff 2000 Series Sport Brake Pads with new brake rotors, you’ll find down the road when the time comes to replace the pads again, the rotors will still be usable enough to last through another set of brake pads. And if you’re installing EBC pads without replacing rotors, pre-chamfered pad edges will mate perfectly against the grooves and lips that normally form on the rotor surfaces, so the meat of the pad makes contact against the rotor center where it counts. These pads also feature a red top layer coating designed to scour glaze and hot spots off worn brake rotors during the break-in process. The coating also serves to provide a higher level of grip to counteract low friction levels that exist before bedding is complete. Built-in shims ensure any high-frequency vibration is absorbed rather than transferred as squealing noise, even under the most extreme weather conditions. EBC backs their replacement brake pads with a 6-month or 10,000 mile warranty against premature wear under normal driving conditions.

- Stage 3 Truck and SUV Brake Kit

-

The EBC Stage 3 Truck and SUV Brake Kit is perfect for all driving styles from everyday driving to light and moderate towing. The kit is also great if you?ve upgraded your truck?s or SUV?s wheels to some bigger ones and your stock brakes just don?t deliver like you want them to. The 6000 Series Greenstuff Pads and the EBC Slotted and Dimpled Rotors welcome the challenge.

Rotors Features:

- Angled slots on rotor surfaces allow superior expulsion of heat, water, brake dust, and friction gases

- Round indents in the rotors surface further increase cooling without the risk of cracking that drill-through holes pose

- Rotors feature finish provides corrosion protection for all non-contact areas

- Brake rotors are unidirectional to the left and right side of your vehicle to maximize effectiveness

- 3GD vented centers feature a wider aperture for air to pass between both rotor sides for superior cooling

- EBC recommends a 500 mile break in period with lighter braking application

Brake Pads Features:

- Engineered to better resist mud, sand, and grit that accumulate on brakes during off-roading

- Nominal friction coefficient of 0.45 under normal driving conditions

- Patented organic AF42/66 pad friction material features a low level of metallic compounds that reduces rotor wear by up to 50%

- Produces a low amount of brake dust

- Backing plate and side edges of brake pad are green powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built in noise-reducing shims

- Patented Brake-In™ red pad surface coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red pad surface coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

- 6-month/10,000 mile manufacturer warranty against premature pad wear under normal driving conditions

EBC pioneered brake rotors with dimple-drilled round indents decades ago to provide a solution to cracking problems that sometimes plague perforated rotors operating under high stress and heat conditions. What makes the 3GD Series Dimpled and Slotted Sport Rotors superior is the presence of both these dimpled indents and straight vent slots. Combined, they provide the superior expulsion of heat, water, brake dust, and friction gas that is needed to keep rotors cool and functional during street performance driving in any weather. Additionally, 3GD rotors feature a wider vented aperture for air to pass between both rotor sides, so metal expands evenly during use and the chance of warpage is minimized. 3GD rotors are designed for use with EBC Greenstuff 4x4 brake pads, Greenstuff 2000 compact car pads, Yellowstuff heavy duty 4x4 brake pads, and Yellowstuff / Redstuff pads created for shorter high performance street or track runs and drifting. 3GD brake rotors are anodized to prevent corrosion, and rotors should be fully ready for use after the first 500 miles of moderate brake application.

For heavier pickup trucks and sport utility vehicles, EBC offers the Greenstuff 6000 Series Truck and SUV Brake Pads to give you longer pad life, low rotor wear, and reduced brake dust. Instead of neck-breaking autobahn grip, Greenstuff 6000 pads are formulated for the unique needs of heavier trucks and sport utilities that venture off-road. Unlike factory original semi-metallic pads, these are constructed from an organic aramid compound which blends Kevlar and Twaron composites to create a harder pad surface that is extremely resistant to dirt, rocks, and sand. While that harder brake pad surface takes longer to wear down, the improved pad life will not come at the expense of your rotors. Because steel wool compounds are pared to minimum levels, you will find a new set of rotors will last through two sets of brake pads. Should you install new pads without replacing rotors, pre-chamfered pad edges will mate perfectly against the grooves and lips that normally form on the rotor surfaces, so the meat of the pad makes contact against the rotor center where it counts. These pads also feature a red top layer coating designed to scour glaze and hot spots off worn brake rotors during the break-in process. As it does that, the coating also serves to provide a higher level of grip to counteract low friction levels that exist before bedding is complete. Built-in shims ensure any high-frequency vibration is absorbed rather than transferred as squealing noise, even under the most extreme weather conditions.

In government R90 tests of replacement brake components, EBC Greenstuff pads have been shown to deliver equivalent performance, bedding, cold temperature operation, and speed sensitivity versus original manufacturer parts. EBC’s patented Greenstuff brake pad material also ensures the pads are soft enough to avoid brake squeal, but not so soft that longevity becomes compromised. Built-in shims ensure any high-frequency vibration is absorbed to prevent squealing even under the most extreme weather conditions. EBC backs Greenstuff 6000 Series Truck and SUV Brake Pads with a 6-month or 10,000 mile warranty against premature wear under normal driving conditions.

- Stage 4 Signature Brake Kit

-

Get increased power with less brake dust no matter what you drive with the EBC Stage 4 Signature Brake Kit. The Ultimax Rotors add the finishing touch to this kit because the slots keep the braking temperatures down, actually improving wet weather braking which is a big deal.

Rotors Features:

- Created to be the lowest noise brake rotors designed for performance applications

- Angled slots on rotor surfaces allow superior expulsion of heat, water, brake dust, and friction gases

- Two sets of slots on rotor surfaces provide even pad wear which creates flat, parallel rotor wear without ridges from developing

- Vented centers feature an aperture for air to pass between both rotor sides for superior cooling

- Rotors feature protective finish to provide corrosion protection for all non-contact areas

- Brake rotors are unidirectional to the left and right side of your vehicle to maximize effectiveness

- EBC recommends a 500 mile break in period with lighter braking application

Brake Pads Features:

- Superior ceramic pad compounds resist heat buildup, dust, and squealing

- Ceramic pad compounds wear slower and last longer than OEM equipment

- Improved safety from shorter stopping distances

- Reduced heat buildup eliminates brake fading that occurs when brake fluid reaches boiling temperature

- Advanced ceramic brake pad compounds produce less dust than OEM factory brake pads

- Ceramic pads eliminate squealing under the most extreme cold or hot temperatures

- 6 month/10,000 mile manufacturer warranty against premature pad wear under normal driving conditions

USR Series Front Sport Slotted Rotors are created for the enthusiast who wants low noise from their brakes while doing a higher level of aggressive driving or towing. Two sets of shallow slots cover all areas of the rotor surfaces so both pads and rotors wear evenly all the way across – preventing the grooves and ridges from building up that cause frictional noise. They also effectively increase the level of heat, water, brake dust, and friction gas expulsion necessary to keep rotors cool and functional during street performance driving in any weather. Additionally, USR Series Front Sport Slotted Rotors feature a vented center for air to pass between both rotor sides, so metal expands evenly during use and the chance of warpage is minimized. USR Series Front Sport Slotted Rotors are designed for use with EBC Greenstuff, Yellowstuff, and Redstuff pads. All areas of the rotors have a protective coating to prevent corrosion, and should be fully ready for use after the first 500 miles of moderate brake application.

Redstuff Ceramic Low Dust Brake Pads by EBC are replacement brake pads that use a Kevlar-based fiber compound enhanced with ceramic particles instead of metallic steel wool found on 99% of vehicles from manufacturers today. Formulated specifically for heavier cars and trucks with high levels of performance, Redstuff pads can handle the heat generated by heavy loads and provide long life while generating minimal dust residue. While they provide a more gradual level of grip than EBC Yellowstuff pads, their braking power is nonetheless a substantial improvement over semi-metallic brake pads. During independent tests at 100 miles per hour, Redstuff brake pads have been shown to reduce the distance it took to stop some vehicles by 50 feet. In the real world, that’s three car lengths – a remarkable safety improvement when what’s important is on the line.

Ceramic brake pads are used in Formula 1, Nascar, and most forms of championship racing for many reasons. When braking at sustained speeds of over 200 miles per hour, enough heat is generated on brake components to make rotors glow. Ceramic brake pads offer the ability to stay cool under the most severe conditions. Used with perforated rotors, heat buildup is reduced so much that brake fade from fluid reaching boiling temperature is all but eliminated. While you may not drive under these conditions, the benefits of these pads can be enjoyed at any speed. Ceramic brake pads are far quieter due to their higher resonant frequency undetectable by human ears, and once the initial bed-in period of 1,500 miles has passed, you’ll rarely hear any noise from Redstuff pads. Equally important, the brake dust that ceramic pads produce is far less, finer in consistency, and non-adhesive to wheel surfaces. You don’t need to drive on a racetrack to enjoy the benefits RedStuff ceramic brake pads offer, and CARiD offers them at a value-packed price that matches what some dealers charge for traditional pads.

- Stage 5 Superstreet Brake Kit

-

The EBC Stage 5 SuperStreet Brake Kit is designed for those looking for heavy-duty high gripping pads and rotors. Thanks to the 4000 Series Yellowstuff Street and Track Pads matched with some of the coolest rotors you?re sure to get smooth, consistent braking every time you hit the brake pedal.

Rotors Features:

- Angled slots on rotor surfaces allow superior expulsion of heat, water, brake dust, and friction gases

- Round indents in the rotors surface further increase cooling without the risk of cracking that drill-through holes pose

- Rotors feature finish provides corrosion protection for all non-contact areas

- Brake rotors are unidirectional to the left and right side of your vehicle to maximize effectiveness

- 3GD vented centers feature a wider aperture for air to pass between both rotor sides for superior cooling

- EBC recommends a 500 mile break in period with lighter braking application

Brake Pads Features:

- Designed to provide an optimum combination of street and racetrack performance

- Unique composition allows high braking friction when brakes are cold

- Features a cold friction rating of 0.5

- Backing plate and side edges of brake pad are yellow powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built in noise-reducing shims

- Provides equivalent performance to GG-rated brake pads

- Patented Brake-In™ red pad surface coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red pad surface coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

- 6 month/10,000 mile manufacturer warranty against premature pad wear under normal driving conditions

EBC pioneered brake rotors with dimple-drilled round indents decades ago to provide a solution to cracking problems that sometimes plague perforated rotors operating under high stress and heat conditions. What makes the 3GD Series Dimpled and Slotted Sport Rotors superior is the presence of both these dimpled indents and straight vent slots. Combined, they provide the superior expulsion of heat, water, brake dust, and friction gas that is needed to keep rotors cool and functional during street performance driving in any weather. Additionally, 3GD rotors feature a wider vented aperture for air to pass between both rotor sides, so metal expands evenly during use and the chance of warpage is minimized. 3GD rotors are designed for use with EBC Greenstuff 4x4 brake pads, Greenstuff 2000 compact car pads, Yellowstuff heavy duty 4x4 brake pads, and Yellowstuff / Redstuff pads created for shorter high performance street or track runs and drifting. 3GD brake rotors are anodized to prevent corrosion, and rotors should be fully ready for use after the first 500 miles of moderate brake application.

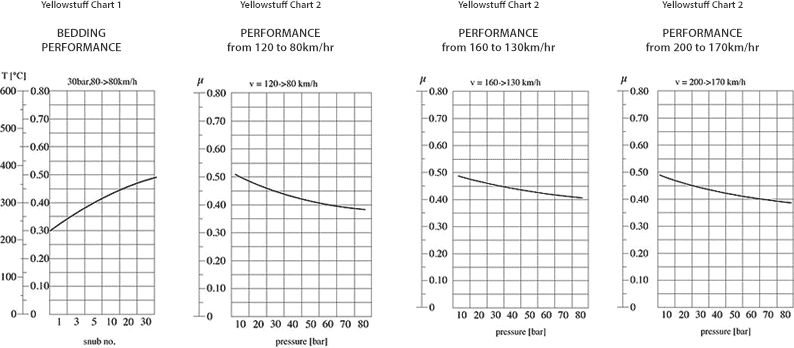

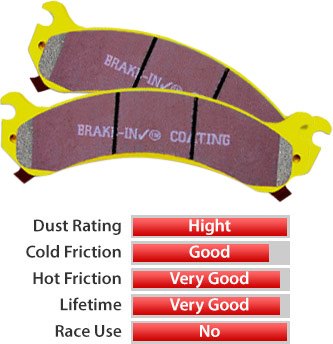

EBC Yellowstuff 4000 "R" Series Full Race Brake Pads deliver fade-free performance on the racetrack, effective grip during street racing and drifting, and comfortable, easy-to-use operation under normal driving conditions. From the Swedish Camaro Cup to Mazda MX5 Miata competitions to SCCA challenges, Yellowstuff Racing Series pads are favored by drivers across a wide range of racing cup events that require the use of stock OEM brake caliper systems. Why? The more exotic aramid fiber construction of Yellowstuff pads is known for its ability to maintain easy controllability and high grip levels at any temperature while also resisting heat buildup and brake fade under severe conditions. EBC conceived the Yellowstuff 4000 line for lighter Japanese vehicles as well as heavier, high-horsepower sedans typically found travelling German autobahns at triple-digit velocities.

If you’re installing Yellowstuff 4000 "R" Series Full Race Brake Pads with new brake rotors, you’ll find down the road when the time comes to replace the pads again, rotors will still be usable enough to last through another set of brake pads. And if you are installing EBC pads without replacing rotors, pre-chamfered pad edges will mate perfectly against the grooves and lips that normally form on the rotor surfaces, so the meat of the pad makes contact against the rotor center where it counts. These pads also feature a red top layer coating designed to scour glaze and hot spots off worn brake rotors during the break-in process. As it does that, the coating also serves to provide a higher level of grip to counteract low friction levels that exist before bedding is complete. Built-in shims ensure any high-frequency vibration is absorbed rather than transferred as squealing noise, even under the most extreme weather conditions. EBC backs their replacement brake pads with a 6-month or 10,000 mile warranty against premature wear under normal driving conditions.

- Stage 6 Track Day Brake Kit

-

The EBC Stage 6 Trackday Brake Kit is designed to deliver the stopping power you need at the racetrack. The Bluestuff Pads work great with the EBC Sport Slotted and Dimpled Rotors to have your vehicle stopped on a dime and off the track.

Rotors Features:

- Angled slots on rotor surfaces allow superior expulsion of heat, water, brake dust, and friction gases

- Round indents in the rotors surface further increase cooling without the risk of cracking that drill-through holes pose

- Rotors feature finish provides corrosion protection for all non-contact areas

- Brake rotors are unidirectional to the left and right side of your vehicle to maximize effectiveness

- 3GD vented centers feature a wider aperture for air to pass between both rotor sides for superior cooling

- EBC recommends a 500 mile break in period with lighter braking application

Brake Pads Features:

- Designed for use with low drag multi-piston, performance brake calipers only

- Formulated for optimum heavy-duty racetrack performance

- Features two gaps in the pad surface instead of one for increased cooling and debris collection

- Backing plates feature vibration-balancing weights to reduce squealing noise under high stress

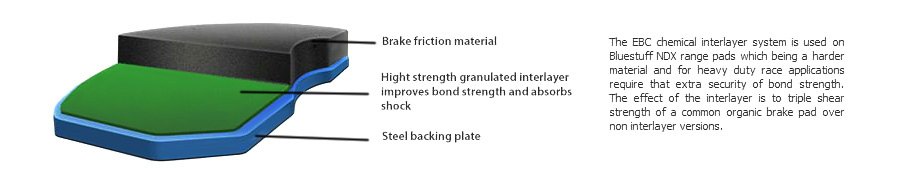

- Pads are bonded to backing plates with a chemical layer that triples separation resistance

- Pads provide progressive brake feel and are safe for street use also

- Organic aramid fiber construction maintains high level of grip when pads are cold or extremely hot

- Backing plate and side edges of brake pad are blue powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Pads come new with rough, heat-scorched surface designed for improved bedding with rough or worn rotors

- 200 miles of gentle use is recommended during pad break-in period

- 6 month/10,000 mile manufacturer warranty against premature pad wear under normal driving conditions

EBC pioneered brake rotors with dimple-drilled round indents decades ago to provide a solution to cracking problems that sometimes plague perforated rotors operating under high stress and heat conditions. What makes the 3GD Series Dimpled and Slotted Sport Rotors superior is the presence of both these dimpled indents and straight vent slots. Combined, they provide the superior expulsion of heat, water, brake dust, and friction gas that is needed to keep rotors cool and functional during street performance driving in any weather. Additionally, 3GD rotors feature a wider vented aperture for air to pass between both rotor sides, so metal expands evenly during use and the chance of warpage is minimized. 3GD rotors are designed for use with EBC Greenstuff 4x4 brake pads, Greenstuff 2000 compact car pads, Yellowstuff heavy duty 4x4 brake pads, and Yellowstuff / Redstuff pads created for shorter high performance street or track runs and drifting. 3GD brake rotors are anodized to prevent corrosion, and rotors should be fully ready for use after the first 500 miles of moderate brake application.

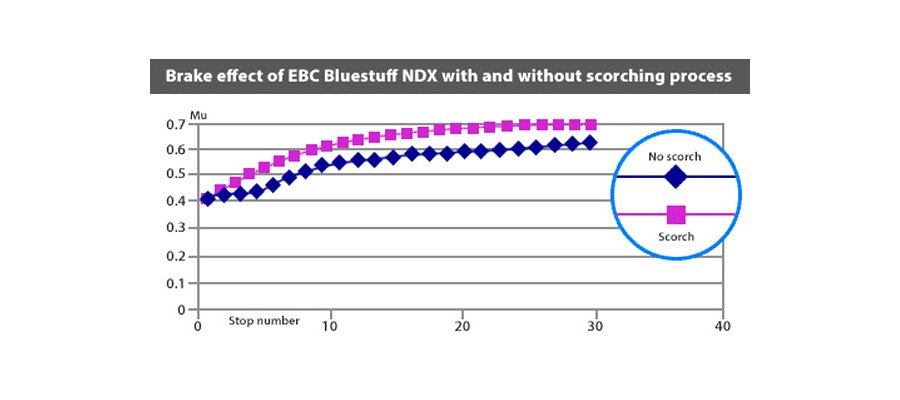

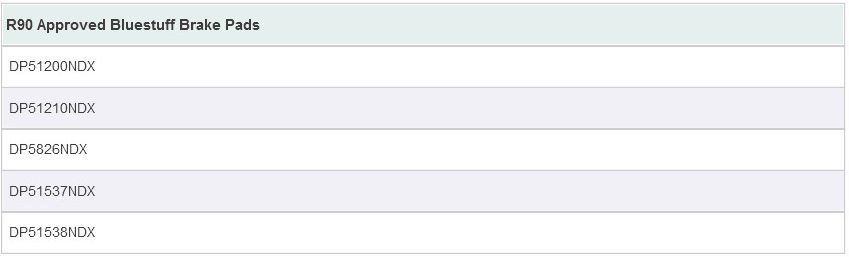

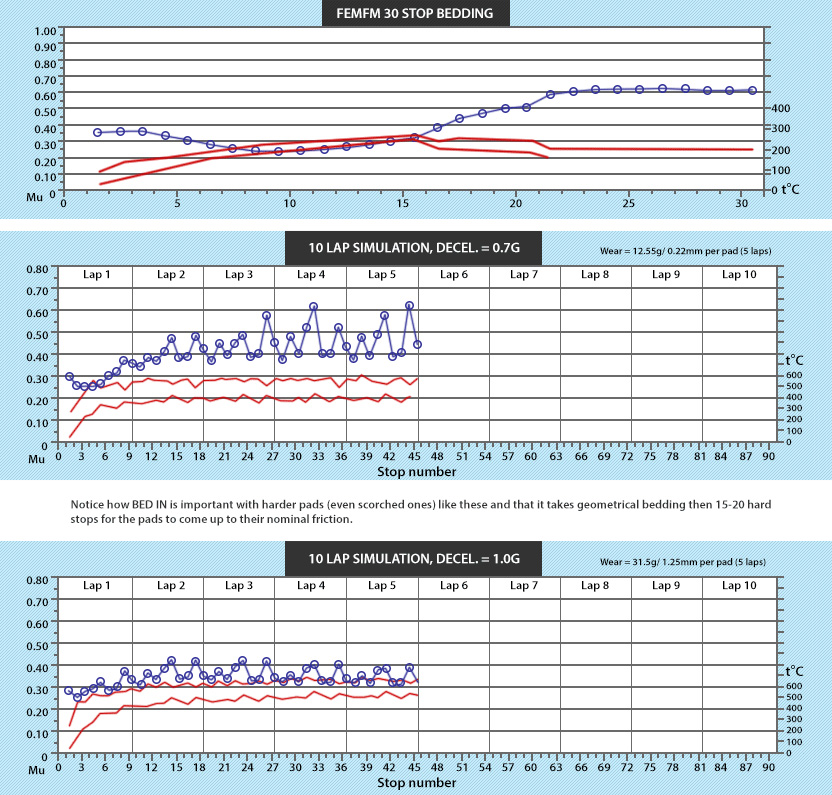

While EBC Yellowstuff brake pads are designed for racetrack use with standard OE brake calipers, Bluestuff pads are designed to provide an even higher level of performance for the racing enthusiast who owns a vehicle equipped with superior multi-piston, high-performance brake calipers. Bluestuff NDX Formula Racing Brake Pads are formulated to take the extra squeezing power of multi-piston calipers and make the most of it, offering massive levels of grip when you need to scrub off speed fast. And while these brakes will let you stop on a dime from triple-digit speeds, you will also be impressed with their gradual and progressive application that makes them easy to live with and use on the street. Bluestuff pads come designed for grip the minute you put them on your vehicle with a rougher, heat-scorched top layer for the best initial mating with new or worn brake rotor surfaces. Once the pads have fully broken in, the grip they are known for is available at all times whether the brakes are cold on an icy morning or hot during an endurance race.

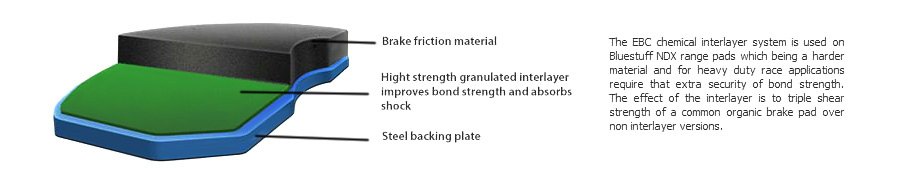

The organic aramid fiber construction of Bluestuff pads resists heat buildup that plagues inferior pads, so you won’t have to compensate for reduced effectiveness after brake fluid gets hot enough to boil in the lines. And Bluestuff pads are designed to hold together under extreme, heavy use. Instead of using rivets to secure pad material and backing plate together, Bluestuff pads use an additional layer between the two in order to form a strong chemical bond that provides three times the resistance of pad separation or shear. Four balancing weights built in to the backing plates of Bluestuff pads ensure high-frequency vibration is cancelled out to eliminate squealing noise. While EBC backs their replacement brake pads with a 6-month or 10,000 mile warranty against premature wear under normal driving conditions, they do not cover excessive wear or damage resulting from racetrack or drifting use.

- Stage 7 Race Brake Kit

-

The EBC Stage 7 Race Brake Kit was created for serious race cars that need serious pads and rotors. The kit uses EBC?s most aggressive components for the best stopping power you can get. The Orangestuff Brake Pads are designed for maximum cold friction that stays constant even at high temperatures, while the High Carbon Blade Rotors have twice the carbon content of normal rotors for outstanding thermal stability.

Rotors Features:

- Powder coat finish provides corrosion protection for all non-contact areas

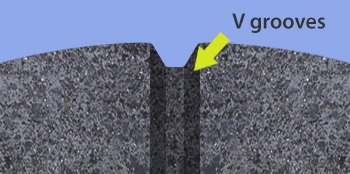

- V-shaped slots on rotor surfaces allow increased expulsion of heat, water, brake dust, and friction gases

- Recommended by EBC for use on performance street driving and racing with lighter weight vehicles

- High carbon content doubles the levels of some competitors to prevent brake shudder, heat cracking, and high-frequency vibrations which cause squealing

- Vented center allows air to pass between both rotor sides for more effective cooling

- V-shaped slots have a 1mm depth that indicates rotors need replacement when slots have worn away completely

- EBC recommends a 500 mile break in period with lighter braking application

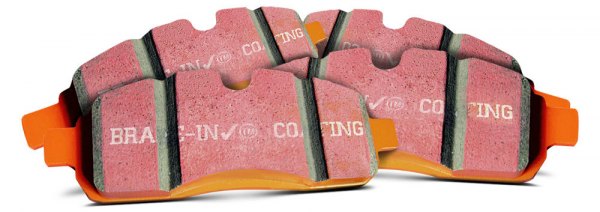

Brake Pads Features:

- Not legal for street use

- High-grip pads bite quickly and feature less progressive brake application

- Friction level of .6 hot and .5 cold makes these EBC’s highest and fastest-gripping pads

- Recommended for experienced racetrack drivers only

- Highly abrasive semi-metallic pad construction is designed to provide the best grip at the expense of brake rotor life

- Designed for use with low drag multi-piston, performance brake calipers only

- Features two cooling gaps in the pad surface instead of one for increased cooling and debris collection

- Backing plates feature vibration-balancing weights to reduce squealing noise under high stress

- Pads are bonded to backing plates with a layer of chemical bonding material that triples separation resistance

- Backing plate and side edges of brake pad are orange powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Pads come new with rough, heat-scorched surface designed for improved bedding with rough or worn rotors

- 6 month/10,000 mile manufacturer warranty against premature pad wear under normal driving conditions

EBC High Carbon Blade Sport Rotors are blended to offer performance drivers the absolute lowest amount of brake shudder, noise and heat buildup. Unlike brake rotors from competitors, High Carbon Blade Sport Rotors are cast from “gray” iron which features a high percentage of carbon (roughly 4 percent) and silicone which leads to the formation of graphite during the curing process at EBC’s factory. When graphite is present, the rotor itself takes on qualities of a denser, softer material. Heat is more evenly dispersed to reduce warping, cracks are less likely, and vibration-related noise is greatly reduced. High Carbon Blade rotors are also powder coated with a patented Geomet finish to keep corrosion at bay, and rotors should be fully ready for performance driving after a 500 mile break-in period.

For the longest and hardest non-street racing applications, the brake experts at EBC have created the ultimate set of replacement brake pads. Orangestuff Full Race Brake Pads are constructed of a specially engineered metallic material that bites quickly and severely into brake rotors to provide powerful grip for any heavy racecar. Unlike EBC’s Bluestuff organic pads that are designed for racing AND street use, these Orangestuff metallic pads are legal for racetrack use only because their level of grip makes them more difficult to apply gradually during everyday street driving. And while Bluestuff pad material prolongs brake rotor life, Orangestuff’s extremely abrasive characteristics which give it such great braking power actually wear the rotors down faster.

Because of the intense heat that can build up on brake components, Orangestuff brake pads are meant to be used only on high-performance brake calipers with multiple pistons that release faster and more completely with less drag. During EBC tests on a dynamometer where a full 1G of stopping force was applied repeatedly, Orangestuff pads survived sustained operation at temperatures of 1,800 degrees Fahrenheit without chipping, cracking, or coming apart. During the dyno test, rotor surfaces were literally glowing red and while the performance of the Orangestuff pads dropped slightly under these conditions, the majority of their effectiveness remained. Instead of using rivets to secure pad material and backing plates together, Orangestuff pads use an additional chemical layer between the two in order to form a strong bond that provides three times the resistance of pad separation or shear. Four balancing weights built in to the backing plates of the pads ensure high-frequency vibration is cancelled out to eliminate squealing noise. While EBC backs their replacement brake pads with a 6-month or 10,000 mile warranty against premature wear under normal driving conditions, they do not cover excessive wear or damage resulting from racetrack or drifting use.

- Stage 8 Super Truck Dimpled and Slotted Brake Kit

-

Replace your old, worn out brakes with better performing pads and rotors from EBC. The Stage 8 Sport Brake Kit is designed to increase your stopping power and produce less brake dust than your stock brakes. The anodized layer is designed to disappear in the area that the brake pads contact the rotor.

Rotors Features:

- Angled slots on rotor surfaces allow superior expulsion of heat, water, brake dust, and friction gases

- Round indents in the rotors surface further increase cooling without the risk of cracking that drill-through holes pose

- Black GEOMET and NITROTHERM™ anti corrosive finish

- Brake rotors are unidirectional to the left and right side of your vehicle to maximize effectiveness

- 3GD vented centers feature a wider aperture for air to pass between both rotor sides for superior cooling

- EBC recommends a 500 mile break in period with lighter braking application

- This type of rotors are designed to make a buzzing/rubbing sound

Brake Pads Features:

- British made top quality product

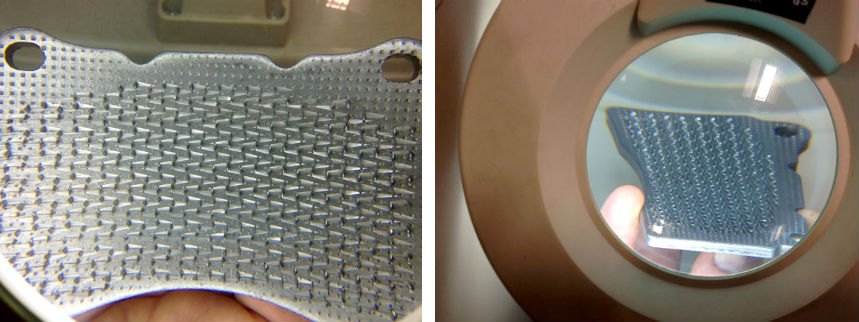

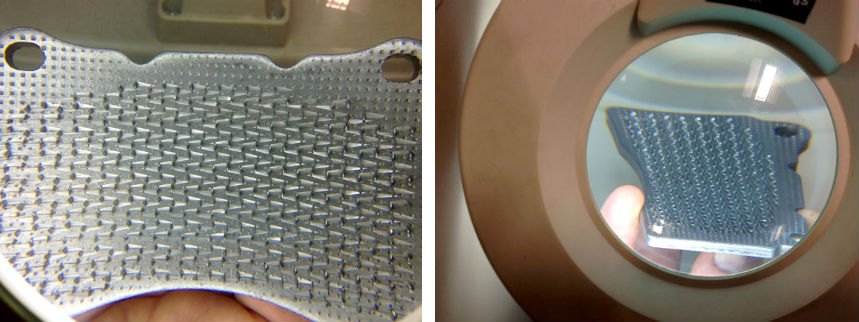

- Backing plate steels feature NUCAP NRS system hook technology for 5 times the bond strength of conventional pads

- Noiseless material with piston insert NUCAP insulator shims

- High volume Vee grooves in pads to vent better and remove dirt dust and debris actually cooling the centre hot areas of the pad better

- Fade free brake material capable of a wide range of operational temperatures

- More brake "grip" than stock and most low cost aftermarket pads at less cost than original parts

- Longer life than any other pad EBC has ever made and probably, longer life than anything else out there in the aftermarket, including stock pads

- Features red "brake in? surface coating for instant safe braking after install

EBC pioneered brake rotors with dimple-drilled round indents decades ago to provide a solution to cracking problems that sometimes plague perforated rotors operating under high stress and heat conditions. What makes the 3GD Series Dimpled and Slotted Sport Rotors superior is the presence of both these dimpled indents and straight vent slots. Combined, they provide the superior expulsion of heat, water, brake dust, and friction gas that is needed to keep rotors cool and functional during street performance driving in any weather. Additionally, 3GD rotors feature a wider vented aperture for air to pass between both rotor sides, so metal expands evenly during use and the chance of warpage is minimized. 3GD rotors are designed for use with EBC Greenstuff 4x4 brake pads, Greenstuff 2000 compact car pads, Yellowstuff heavy duty 4x4 brake pads, and Yellowstuff / Redstuff pads created for shorter high performance street or track runs and drifting. 3GD brake rotors are anodized to prevent corrosion, and rotors should be fully ready for use after the first 500 miles of moderate brake application.

World-renowned brake experts at EBC have developed over a dozen variations of performance brake components, and each one is crafted to provide a superior level of grip, wear, and performance for uniquely different vehicle sizes, weights, and applications. When the company engineers who created pads that can survive 1,800 degree temperature test runs turn their attention to creating equally impressive brake rotors, you will see rotors finely tuned to deliver impressive looks behind your wheel spokes and last run performance that’s as equally impressive as your first. If you’ve been let down by underperforming brake rotors that didn’t last as long as they should, 3GD Series Dimpled and Slotted Sport Rotors are designed for the long run. If installed at the same time as a new set of EBC long life brake pads, it’s not uncommon for these rotors to last the length of the first set with more than enough life to be used with a second set. All EBC brake rotors are cast to a high metal strength rating of 150 newton meters and are precision CNC machined to be within tolerances of less than 0.05 millimeters. 3GD Series Dimpled and Slotted Sport Rotors are the result of relentless testing and refinement, and when better brake rotors are built it is EBC that will build them.

The UK EFI Bristol factory of EBC Brakes has used new ECO friendly technology to develop a brake pad that has unusually high friction levels yet still has good manners for street use with brake effect being strong from cold when the brake is first applied. The race pedigree of the material used also guarantees effective stopping up to temperatures exceeding 1400 F well above the maximum experienced in heavy braking, towing or downhill descents. Winter testing in Ohio on a fleet five popular light trucks showed us the proof on cold braking in the worst wet and cold conditions where many performance brakes would not even start to show good brake effect. So these are pads that have an extremely wide range of usability.Towing with loads often pushes brakes past their factory limits, in fact have you even checked if the stock brakes on your truck or SUV are good enough for extended towing and hill descents? The new carbon granule based EXTRA DUTY material is also extremely rotor friendly, minimal in dust and noiseless and each set is supplied with revolutionary NUCAP piston insert shims, another first from EBC.

- Stage 9 Super Sleeper Slotted Brake Kit

-

Replace your old, worn out brakes with better performing pads and rotors from EBC. The Stage 9 Sport Brake Kit is designed to increase your stopping power and produce less brake dust than your stock brakes. The anodized layer is designed to disappear in the area that the brake pads contact the rotor.

Rotors Features:

- Created to be the lowest noise brake rotors designed for performance applications

- Angled slots on rotor surfaces allow superior expulsion of heat, water, brake dust, and friction gases

- Two sets of slots on rotor surfaces provide even pad wear which creates flat, parallel rotor wear without ridges from developing

- Black GEOMET and NITROTHERM™ anti corrosive finish

- Brake rotors are unidirectional to the left and right side of your vehicle to maximize effectiveness

- EBC recommends a 500 mile break in period with lighter braking application

Brake Pads Features:

- Designed to provide an optimum combination for street use

- Unique composition allows high braking friction when brakes are cold

- Features a cold friction rating of 0.5

- Backing plate and side edges of brake pad are yellow powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built in noise-reducing shims

- Provides equivalent performance to GG-rated brake pads

- Patented Brake-In™ red pad surface coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red pad surface coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

USR Series Sport Slotted Rotors are created for the enthusiast who wants low noise from their brakes while doing a higher level of aggressive driving or towing. Two sets of shallow slots cover all areas of the rotor surfaces so both pads and rotors wear evenly all the way across – preventing the grooves and ridges from building up that cause frictional noise. They also effectively increase the level of heat, water, brake dust, and friction gas expulsion necessary to keep rotors cool and functional during street performance driving in any weather. Additionally, USR Series Sport Slotted Rotors feature a vented center for air to pass between both rotor sides, so metal expands evenly during use and the chance of warpage is minimized. USR Series Sport Slotted Rotors are designed for use with EBC Greenstuff, Yellowstuff, and Redstuff pads. All areas of the rotors have a protective coating to prevent corrosion, and should be fully ready for use after the first 500 miles of moderate brake application.

The world-renowned brake experts at EBC have developed over a dozen variations of performance brake components, and each one is crafted to provide a superior level of grip, wear, and performance for uniquely different vehicle sizes, weights, and applications. When the company engineers who created pads that can survive 1,800 degree temperature test runs turn their attention to creating equally impressive brake rotors, it will be finely tuned to deliver impressive looks behind your wheel spokes and performance that’s as equally impressive on your last run as your first. If you’ve been let down by underperforming brake rotors that didn’t last as long as they should, USR Series Sport Slotted Rotors are designed for the long run. If installed at the same time as a new set of EBC brake pads, it’s not uncommon for these rotors to last the length of the first set with more than enough life to be used with a second set. USR Series Sport Slotted Rotors are the result of relentless testing and refinement, and when better brake rotors are built it is EBC that will build them.

EBC Yellowstuff 1793 compound is a true winner all round, it has high friction from cold, not requiring warm up for street use yet when loaded up and really hot the brakes just get better. Even up to truck weights these pads grip and do not heat fade. They also suitable and the most fastest brake pads for Trackday and Drift racing. EBC yellows are ECE Brake safety tested which means they must work perfectly from cold at least as good or better than stock pads. When Yellowstuff see some heat (which is not tested for in the ECE R 90 brake safety regulations) they really show their pedigree. On Japanese cars built with lower friction FF rated pads these deliver a full grade higher stopping and on German cars built with GG these are about the only aftermarket pads that will match or beat the pretty good German OE spec pads and that takes some doing.

- Stage 10 Super Sport Dimpled and Slotted Brake Kit

-

Replace your old, worn out brakes with better performing pads and rotors from EBC. The Stage 10 Sport Brake Kit is designed to increase your stopping power and produce less brake dust than your stock brakes. The anodized layer is designed to disappear in the area that the brake pads contact the rotor.

Rotors Features:

- Angled slots on rotor surfaces allow superior expulsion of heat, water, brake dust, and friction gases

- Round indents in the rotors surface further increase cooling without the risk of cracking that drill-through holes pose

- Black GEOMET and NITROTHERM™ anti corrosive finish

- Brake rotors are unidirectional to the left and right side of your vehicle to maximize effectiveness

- 3GD vented centers feature a wider aperture for air to pass between both rotor sides for superior cooling

- EBC recommends a 500 mile break in period with lighter braking application

- This type of rotors are designed to make a buzzing/rubbing sound

Brake Pads Features:

- Designed to give a high level of grip upon initial brake application

- Engineered for optimum performance on lighter vehicles with horsepower ratings under 200

- Nominal friction coefficient of 0.55

- Offers superior brake performance up to temperatures of 1,100° Fahrenheit

- Patented organic AF42/66 pad friction material features a low level of metallic compounds that reduces rotor wear by up to 50%

- Produces low amount of brake dust

- Backing plate and side edges of brake pad are green powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built in noise-reducing shims

- Patented Brake-In™ red pad surface coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red pad surface coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

EBC pioneered brake rotors with dimple-drilled round indents decades ago to provide a solution to cracking problems that sometimes plague perforated rotors operating under high stress and heat conditions. What makes the 3GD Series Dimpled and Slotted Sport Rotors superior is the presence of both these dimpled indents and straight vent slots. Combined, they provide the superior expulsion of heat, water, brake dust, and friction gas that is needed to keep rotors cool and functional during street performance driving in any weather. Additionally, 3GD rotors feature a wider vented aperture for air to pass between both rotor sides, so metal expands evenly during use and the chance of warpage is minimized. 3GD rotors are designed for use with EBC Greenstuff 4x4 brake pads, Greenstuff 2000 compact car pads, Yellowstuff heavy duty 4x4 brake pads, and Yellowstuff / Redstuff pads created for shorter high performance street or track runs and drifting. 3GD brake rotors are anodized to prevent corrosion, and rotors should be fully ready for use after the first 500 miles of moderate brake application.

World-renowned brake experts at EBC have developed over a dozen variations of performance brake components, and each one is crafted to provide a superior level of grip, wear, and performance for uniquely different vehicle sizes, weights, and applications. When the company engineers who created pads that can survive 1,800 degree temperature test runs turn their attention to creating equally impressive brake rotors, you will see rotors finely tuned to deliver impressive looks behind your wheel spokes and last run performance that’s as equally impressive as your first. If you’ve been let down by underperforming brake rotors that didn’t last as long as they should, 3GD Series Dimpled and Slotted Sport Rotors are designed for the long run. If installed at the same time as a new set of EBC long life brake pads, it’s not uncommon for these rotors to last the length of the first set with more than enough life to be used with a second set. All EBC brake rotors are cast to a high metal strength rating of 150 newton meters and are precision CNC machined to be within tolerances of less than 0.05 millimeters. 3GD Series Dimpled and Slotted Sport Rotors are the result of relentless testing and refinement, and when better brake rotors are built it is EBC that will build them.

For less powerful vehicles that don’t usually travel at triple-digit velocity, EBC Greenstuff 2000 Series Sport replacement brake pads offer better braking power at real world driving speeds and are thus formulated to provide longer pad life instead of autobahn grip. Sized and fitted to match the exact tolerances of original equipment, these pads fit properly, wear evenly, and avoid rattling or squealing. A patented metallic aramid compound uses DuPont Kevlar and Twaron composites to minimize the amount of steel wool necessary, so these pads cause far less abrasive wear on rotors without compromising brake pad efficiency or longevity. In government R90 tests of replacement brake components, EBC pads have been shown to deliver equivalent performance, bedding, cold temperature operation, and speed sensitivity versus original manufacturer parts. EBC’s patented brake pad material also ensures the pads are soft enough to avoid brake squealing but not so soft that longevity becomes compromised. On some German vehicles, you may even see longer life with EBC pads than the original factory brake pads.

If you’re installing Greenstuff 2000 Series Sport Brake Pads with new brake rotors, you’ll find down the road when the time comes to replace the pads again, the rotors will still be usable enough to last through another set of brake pads. And if you’re installing EBC pads without replacing rotors, pre-chamfered pad edges will mate perfectly against the grooves and lips that normally form on the rotor surfaces, so the meat of the pad makes contact against the rotor center where it counts. These pads also feature a red top layer coating designed to scour glaze and hot spots off worn brake rotors during the break-in process. The coating also serves to provide a higher level of grip to counteract low friction levels that exist before bedding is complete. Built-in shims ensure any high-frequency vibration is absorbed rather than transferred as squealing noise, even under the most extreme weather conditions.

- Stage 11 Light Sport Plain Brake Kit

-

Replace your old, worn out brakes with better performing pads and rotors from EBC. The Stage 11 Sport Brake Kit is designed to increase your stopping power and produce less brake dust than your stock brakes. The anodized layer is designed to disappear in the area that the brake pads contact the rotor.

Rotors Features:

- Sized and shaped to original equipment specifications with extremely tight tolerances

- Designed to meet or reduce factory levels of heat buildup, brake noise, vibration, and wear

- Black GEOMET and NITROTHERM™ anti corrosive finish

- Recommended by EBC for normal street driving, high performance street driving, truck or SUV use, drifting, and short track runs

- High quality "gray" iron features a higher carbon content to reduce brake shudder, heat cracking, and high-frequency vibrations which cause squealing

- EBC recommends a 500 mile break in period with lighter braking application

Brake Pads Features:

- Designed to give a high level of grip upon initial brake application

- Engineered for optimum performance on lighter vehicles with horsepower ratings under 200

- Nominal friction coefficient of 0.55

- Offers superior brake performance up to temperatures of 1,100° Fahrenheit

- Patented organic AF42/66 pad friction material features a low level of metallic compounds that reduces rotor wear by up to 50%

- Produces low amount of brake dust

- Backing plate and side edges of brake pad are green powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built in noise-reducing shims

- Patented Brake-In™ red pad surface coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red pad surface coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

Why pay dealership prices that are marked up 100% when you can purchase EBC high-quality RK Series Premium OE Replacement rotors for less? Unlike cheaper, inferior replacement rotors that may look identical to original equipment, EBC builds these to match original factory dimensions and machines them to extremely tight tolerances. But they did not stop there. EBC has applied their engineering expertise to create an iron compound that exceeds the quality of most original material blends, so these rotors actually improve on factory levels of heat buildup, brake noise, vibration, and wear. A higher percentage of carbon and silicone is present which leads to the formation of graphite during the curing process. When graphite is present, the rotor itself takes on qualities of a denser, softer material. Heat is more evenly dispersed to reduce warping, cracks are less likely, and vibration-related noise is greatly reduced. RK Series Premium OE Replacement Rotor Kit is anodized for corrosion resistance, and rotors should be fully ready for performance driving after a 500 mile break-in period.

The world-renowned brake experts at EBC have developed over a dozen variations of performance brake components, and each one is crafted to provide a superior level of grip, wear, and performance for uniquely different vehicle sizes, weights, and applications. When the company engineers who created pads that can survive 1,800 degree temperature test runs turn their attention to creating equally impressive brake rotors, you will see rotors finely tuned to deliver impressive looks behind your wheel spokes and last run performance that’s as equally impressive as your first. If you’ve been let down by underperforming brake rotors that didn’t last as long as they should, RK Series Premium OE Replacement Rotor kit is designed for the long run. If installed at the same time as a new set of EBC long life brake pads, it’s not uncommon for these rotors to last the length of the first set with more than enough life to be used with a second set. All EBC brake rotors are cast to a high metal strength rating of 150 newton meters and are precision CNC machined to be within tolerances of less than 0.05 millimeters. RK Series Premium OE Replacement Rotor Kit is the result of relentless testing and refinement, and when better brake rotors are built it is EBC that will build them.

For less powerful vehicles that don’t usually travel at triple-digit velocity, EBC Greenstuff 2000 Series Sport replacement brake pads offer better braking power at real world driving speeds and are thus formulated to provide longer pad life instead of autobahn grip. Sized and fitted to match the exact tolerances of original equipment, these pads fit properly, wear evenly, and avoid rattling or squealing. A patented metallic aramid compound uses DuPont Kevlar and Twaron composites to minimize the amount of steel wool necessary, so these pads cause far less abrasive wear on rotors without compromising brake pad efficiency or longevity. In government R90 tests of replacement brake components, EBC pads have been shown to deliver equivalent performance, bedding, cold temperature operation, and speed sensitivity versus original manufacturer parts. EBC’s patented brake pad material also ensures the pads are soft enough to avoid brake squealing but not so soft that longevity becomes compromised. On some German vehicles, you may even see longer life with EBC pads than the original factory brake pads.

If you’re installing Greenstuff 2000 Series Sport Brake Pads with new brake rotors, you’ll find down the road when the time comes to replace the pads again, the rotors will still be usable enough to last through another set of brake pads. And if you’re installing EBC pads without replacing rotors, pre-chamfered pad edges will mate perfectly against the grooves and lips that normally form on the rotor surfaces, so the meat of the pad makes contact against the rotor center where it counts. These pads also feature a red top layer coating designed to scour glaze and hot spots off worn brake rotors during the break-in process. The coating also serves to provide a higher level of grip to counteract low friction levels that exist before bedding is complete. Built-in shims ensure any high-frequency vibration is absorbed rather than transferred as squealing noise, even under the most extreme weather conditions.

- Stage 12 Light Signature Plain Brake Kit

-

Replace your old, worn out brakes with better performing pads and rotors from EBC. The Stage 12 Sport Brake Kit is designed to increase your stopping power and produce less brake dust than your stock brakes. The anodized layer is designed to disappear in the area that the brake pads contact the rotor.

Rotors Features:

- Sized and shaped to original equipment specifications with extremely tight tolerances

- Designed to meet or reduce factory levels of heat buildup, brake noise, vibration, and wear

- Black GEOMET and NITROTHERM™ anti corrosive finish

- Recommended by EBC for normal street driving, high performance street driving, truck or SUV use, drifting, and short track runs

- High quality "gray" iron features a higher carbon content to reduce brake shudder, heat cracking, and high-frequency vibrations which cause squealing

- EBC recommends a 500 mile break in period with lighter braking application

Brake Pads Features:

- Superior ceramic pad compounds resist heat buildup, dust, and squealing

- Ceramic pad compounds wear slower and last longer than OEM equipment

- Improved safety from shorter stopping distances

- Reduced heat buildup eliminates brake fading that occurs when brake fluid reaches boiling temperature

- Advanced ceramic brake pad compounds produce less dust than OEM factory brake pads

- Ceramic pads eliminate squealing under the most extreme cold or hot temperatures

Why pay dealership prices that are marked up 100% when you can purchase EBC high-quality RK Series Premium OE Replacement rotors for less? Unlike cheaper, inferior replacement rotors that may look identical to original equipment, EBC builds these to match original factory dimensions and machines them to extremely tight tolerances. But they did not stop there. EBC has applied their engineering expertise to create an iron compound that exceeds the quality of most original material blends, so these rotors actually improve on factory levels of heat buildup, brake noise, vibration, and wear. A higher percentage of carbon and silicone is present which leads to the formation of graphite during the curing process. When graphite is present, the rotor itself takes on qualities of a denser, softer material. Heat is more evenly dispersed to reduce warping, cracks are less likely, and vibration-related noise is greatly reduced. RK Series Premium OE Replacement Rotor Kit is anodized for corrosion resistance, and rotors should be fully ready for performance driving after a 500 mile break-in period.

The world-renowned brake experts at EBC have developed over a dozen variations of performance brake components, and each one is crafted to provide a superior level of grip, wear, and performance for uniquely different vehicle sizes, weights, and applications. When the company engineers who created pads that can survive 1,800 degree temperature test runs turn their attention to creating equally impressive brake rotors, you will see rotors finely tuned to deliver impressive looks behind your wheel spokes and last run performance that’s as equally impressive as your first. If you’ve been let down by underperforming brake rotors that didn’t last as long as they should, RK Series Premium OE Replacement Rotor kit is designed for the long run. If installed at the same time as a new set of EBC long life brake pads, it’s not uncommon for these rotors to last the length of the first set with more than enough life to be used with a second set. All EBC brake rotors are cast to a high metal strength rating of 150 newton meters and are precision CNC machined to be within tolerances of less than 0.05 millimeters. RK Series Premium OE Replacement Rotor Kit is the result of relentless testing and refinement, and when better brake rotors are built it is EBC that will build them.

- Stage 13 Light Street Plain Brake Kit

-

Replace your old, worn out brakes with better performing pads and rotors from EBC. The Stage 13 Sport Brake Kit is designed to increase your stopping power and produce less brake dust than your stock brakes. The anodized layer is designed to disappear in the area that the brake pads contact the rotor.

Rotors Features:

- Sized and shaped to original equipment specifications with extremely tight tolerances

- Designed to meet or reduce factory levels of heat buildup, brake noise, vibration, and wear

- Black GEOMET and NITROTHERM™ anti corrosive finish

- Recommended by EBC for normal street driving, high performance street driving, truck or SUV use, drifting, and short track runs

- High quality "gray" iron features a higher carbon content to reduce brake shudder, heat cracking, and high-frequency vibrations which cause squealing

- EBC recommends a 500 mile break in period with lighter braking application

Brake Pads Features:

- Designed to provide an optimum combination for street use

- Unique composition allows high braking friction when brakes are cold

- Features a cold friction rating of 0.5

- Backing plate and side edges of brake pad are yellow powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built in noise-reducing shims

- Provides equivalent performance to GG-rated brake pads

- Patented Brake-In™ red pad surface coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red pad surface coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

Why pay dealership prices that are marked up 100% when you can purchase EBC high-quality RK Series Premium OE Replacement rotors for less? Unlike cheaper, inferior replacement rotors that may look identical to original equipment, EBC builds these to match original factory dimensions and machines them to extremely tight tolerances. But they did not stop there. EBC has applied their engineering expertise to create an iron compound that exceeds the quality of most original material blends, so these rotors actually improve on factory levels of heat buildup, brake noise, vibration, and wear. A higher percentage of carbon and silicone is present which leads to the formation of graphite during the curing process. When graphite is present, the rotor itself takes on qualities of a denser, softer material. Heat is more evenly dispersed to reduce warping, cracks are less likely, and vibration-related noise is greatly reduced. RK Series Premium OE Replacement Rotor Kit is anodized for corrosion resistance, and rotors should be fully ready for performance driving after a 500 mile break-in period.

The world-renowned brake experts at EBC have developed over a dozen variations of performance brake components, and each one is crafted to provide a superior level of grip, wear, and performance for uniquely different vehicle sizes, weights, and applications. When the company engineers who created pads that can survive 1,800 degree temperature test runs turn their attention to creating equally impressive brake rotors, you will see rotors finely tuned to deliver impressive looks behind your wheel spokes and last run performance that’s as equally impressive as your first. If you’ve been let down by underperforming brake rotors that didn’t last as long as they should, RK Series Premium OE Replacement Rotor kit is designed for the long run. If installed at the same time as a new set of EBC long life brake pads, it’s not uncommon for these rotors to last the length of the first set with more than enough life to be used with a second set. All EBC brake rotors are cast to a high metal strength rating of 150 newton meters and are precision CNC machined to be within tolerances of less than 0.05 millimeters. RK Series Premium OE Replacement Rotor Kit is the result of relentless testing and refinement, and when better brake rotors are built it is EBC that will build them.

EBC Yellowstuff 1793 compound is a true winner all round, it has high friction from cold, not requiring warm up for street use yet when loaded up and really hot the brakes just get better. Even up to truck weights these pads grip and do not heat fade. They also suitable and the most fastest brake pads for Trackday and Drift racing. EBC yellows are ECE Brake safety tested which means they must work perfectly from cold at least as good or better than stock pads. When Yellowstuff see some heat (which is not tested for in the ECE R 90 brake safety regulations) they really show their pedigree. On Japanese cars built with lower friction FF rated pads these deliver a full grade higher stopping and on German cars built with GG these are about the only aftermarket pads that will match or beat the pretty good German OE spec pads and that takes some doing.

- Stage 14 Light Truck and SUV Plain Brake Kit

-

Replace your old, worn out brakes with better performing pads and rotors from EBC. The Stage 14 Sport Brake Kit is designed to increase your stopping power and produce less brake dust than your stock brakes. The anodized layer is designed to disappear in the area that the brake pads contact the rotor.

Rotors Features:

- Sized and shaped to original equipment specifications with extremely tight tolerances

- Designed to meet or reduce factory levels of heat buildup, brake noise, vibration, and wear

- Black GEOMET and NITROTHERM™ anti corrosive finish

- Recommended by EBC for normal street driving, high performance street driving, truck or SUV use, drifting, and short track runs

- High quality "gray" iron features a higher carbon content to reduce brake shudder, heat cracking, and high-frequency vibrations which cause squealing

- EBC recommends a 500 mile break in period with lighter braking application

Brake Pads Features:

- Engineered to better resist mud, sand, and grit that accumulate on brakes during off-roading

- Nominal friction coefficient of 0.45 under normal driving conditions

- Patented organic AF42/66 pad friction material features a low level of metallic compounds that reduces rotor wear by up to 50%

- Produces a low amount of brake dust

- Backing plate and side edges of brake pad are green powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built in noise-reducing shims

- Patented Brake-In™ red pad surface coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red pad surface coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

Why pay dealership prices that are marked up 100% when you can purchase EBC high-quality RK Series Premium OE Replacement rotors for less? Unlike cheaper, inferior replacement rotors that may look identical to original equipment, EBC builds these to match original factory dimensions and machines them to extremely tight tolerances. But they did not stop there. EBC has applied their engineering expertise to create an iron compound that exceeds the quality of most original material blends, so these rotors actually improve on factory levels of heat buildup, brake noise, vibration, and wear. A higher percentage of carbon and silicone is present which leads to the formation of graphite during the curing process. When graphite is present, the rotor itself takes on qualities of a denser, softer material. Heat is more evenly dispersed to reduce warping, cracks are less likely, and vibration-related noise is greatly reduced. RK Series Premium OE Replacement Rotor Kit is anodized for corrosion resistance, and rotors should be fully ready for performance driving after a 500 mile break-in period.

The world-renowned brake experts at EBC have developed over a dozen variations of performance brake components, and each one is crafted to provide a superior level of grip, wear, and performance for uniquely different vehicle sizes, weights, and applications. When the company engineers who created pads that can survive 1,800 degree temperature test runs turn their attention to creating equally impressive brake rotors, you will see rotors finely tuned to deliver impressive looks behind your wheel spokes and last run performance that’s as equally impressive as your first. If you’ve been let down by underperforming brake rotors that didn’t last as long as they should, RK Series Premium OE Replacement Rotor kit is designed for the long run. If installed at the same time as a new set of EBC long life brake pads, it’s not uncommon for these rotors to last the length of the first set with more than enough life to be used with a second set. All EBC brake rotors are cast to a high metal strength rating of 150 newton meters and are precision CNC machined to be within tolerances of less than 0.05 millimeters. RK Series Premium OE Replacement Rotor Kit is the result of relentless testing and refinement, and when better brake rotors are built it is EBC that will build them.

For heavier pickup trucks and sport utility vehicles, EBC offers the Greenstuff 6000 Series Truck and SUV Brake Pads to give you longer pad life, low rotor wear, and reduced brake dust. Instead of neck-breaking autobahn grip, Greenstuff 6000 pads are formulated for the unique needs of heavier trucks and sport utilities that venture off-road. Unlike factory original semi-metallic pads, these are constructed from an organic aramid compound which blends Kevlar and Twaron composites to create a harder pad surface that is extremely resistant to dirt, rocks, and sand. While that harder brake pad surface takes longer to wear down, the improved pad life will not come at the expense of your rotors. Because steel wool compounds are pared to minimum levels, you will find a new set of rotors will last through two sets of brake pads. Should you install new pads without replacing rotors, pre-chamfered pad edges will mate perfectly against the grooves and lips that normally form on the rotor surfaces, so the meat of the pad makes contact against the rotor center where it counts. These pads also feature a red top layer coating designed to scour glaze and hot spots off worn brake rotors during the break-in process. As it does that, the coating also serves to provide a higher level of grip to counteract low friction levels that exist before bedding is complete. Built-in shims ensure any high-frequency vibration is absorbed rather than transferred as squealing noise, even under the most extreme weather conditions.

In government R90 tests of replacement brake components, EBC Greenstuff pads have been shown to deliver equivalent performance, bedding, cold temperature operation, and speed sensitivity versus original manufacturer parts. EBC’s patented Greenstuff brake pad material also ensures the pads are soft enough to avoid brake squeal, but not so soft that longevity becomes compromised. Built-in shims ensure any high-frequency vibration is absorbed to prevent squealing even under the most extreme weather conditions.

- Stage 15 Slotted Brake Kit

-

The kit is also great if you?ve upgraded your truck?s or SUV?s wheels to some bigger ones and your stock brakes just don?t deliver like you want them to. These brake rotors feature multiple slots in a narrow, more angled pattern to create a quieter running surface with a superior level of cooling. Protective finish provides corrosion resistance on non-contact areas. The anodized layer is designed to disappear in the area that the brake pads contact the rotor.

- Created to be the lowest noise brake rotors designed for performance applications

- Angled slots on rotor surfaces allow superior expulsion of heat, water, brake dust, and friction gases

- Two sets of slots on rotor surfaces provide even pad wear which creates flat, parallel rotor wear without ridges from developing

- Black GEOMET™ and NITROTHERM™ anti corrosive finish

- Brake rotors are unidirectional to the left and right side of your vehicle to maximize effectiveness

- EBC recommends a 500 mile break in period with lighter braking application

- British made top quality product

- Backing plate steels feature NUCAP NRS system hook technology for 5 times the bond strength of conventional pads

- Noiseless material with piston insert NUCAP insulator shims

- High volume Vee grooves in pads to vent better and remove dirt dust and debris actually cooling the centre hot areas of the pad better

- Fade free brake material capable of a wide range of operational temperatures

- More brake "grip" than stock and most low cost aftermarket pads at less cost than original parts

- Longer life than any other pad EBC has ever made and EBC thinks, longer life than anything else out there in the aftermarket, including stock pads

- Features red "brake in" surface coating for instant safe braking after install

- Stage 20 Street Plain Brake Kit

-

Enhance your daily driving with confidence and peace of mind. With the EBC Stage 1 Premium Street Brake Kit, you will forget about brake shudder or embarrassing brake squeal when coming to a stop. The kit combines the Ultimax Pads and stock replacement rotors for the ultimate OEM pad and rotor combination at an affordable price.

Rotors Features:

- Sized and shaped to original equipment specifications with extremely tight tolerances

- Designed to meet or reduce factory levels of heat buildup, brake noise, vibration, and wear

- Black GEOMET and NITROTHERM™ anti corrosive finish

- Recommended by EBC for normal street driving, high performance street driving, truck or SUV use, drifting, and short track runs

- High quality "gray" iron features a higher carbon content to reduce brake shudder, heat cracking, and high-frequency vibrations which cause squealing

- Vented center allows air to pass between both rotor sides for more effective cooling

- EBC recommends a 500 mile break in period with lighter braking application

- Patented AF42/66 pad friction material features a low level of metallic compounds that reduces rotor wear by up to 50%

- Produces low amount of brake dust

- Backing plate and side edges of brake pad are black powder coated for resistance to corrosion

- Pad surfaces have chamfered edges to reduce contact against rotor lip that forms over time and causes squealing

- Center gap allows for proper heat expansion of brake pads

- Built in noise-reducing shims

- Patented Brake-In™ red top coating provides better grip during the first 100 miles after new pads are installed

- Patented Brake-In™ red top coating scours off any existing glaze or heat spots from brake rotor surface for more even surface mating

Brake Pads Features: